UV Resistant Outdoor Use 3d Filament Petg for industry use

- Dowell 3d

- China

- In a week after payment

- 10000kg/week

PETG has the advantage of printing easily like PLA, but offering higher temp and impact resistance like ABS.

Nearly ZERO warpage prints , extremely strong layer bonds , little to no odor at all.

UV Resistant Outdoor Use 3d Filament PETG for industry use

Dowell Electronics Technology CO., Ltd is a high-tech enterprise specializing in R&D, manufacturing and sales of 3D printer and 3D print material.

Dowell3d PETG 3d print material filament used non-toxic imported raw materials. After strict screening and quality control, the produced 3d filament are winding neatly, high strength,stable diameter 1.75mm(±0.02mm), smooth extrusion without plugging, and not easy to warping.

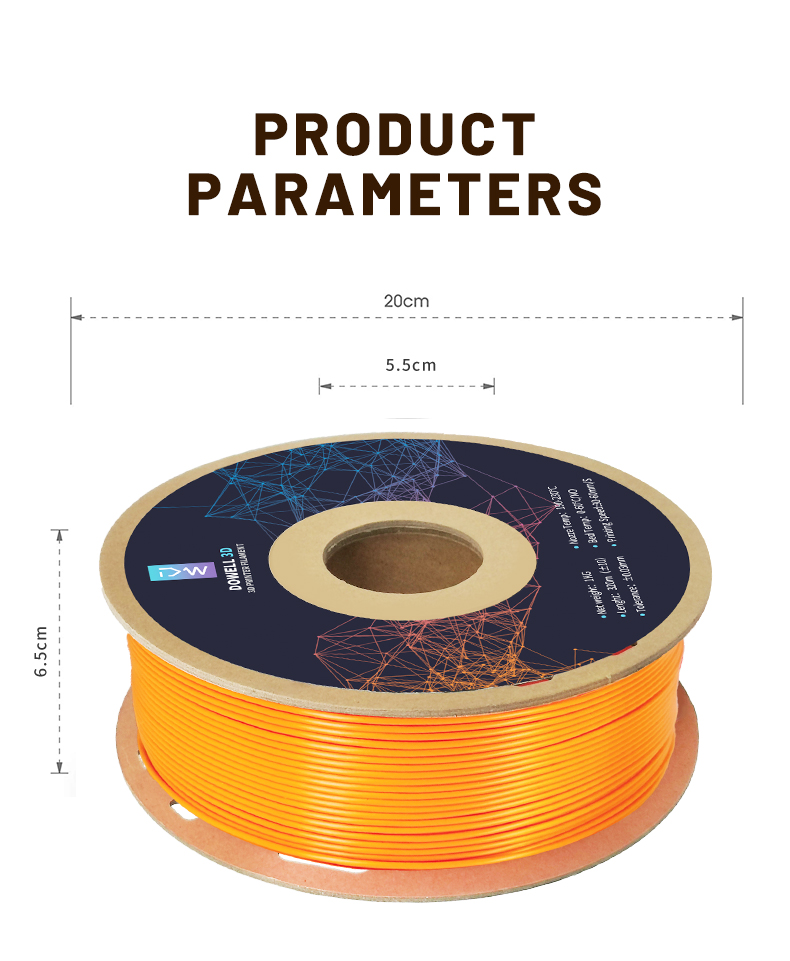

| Specification of Dowell 3d PETG filament | |

| Product | PETG filament |

| Diameter | 1.75mm /2.85mm /3.0mm |

| Recommend print temp | 220-250°c |

| Recommend bed temp | 60-80°c |

| Recommend print speed | 50-100mm/s |

| Melt mass flow rate | 20g/10min (210°c/2.16kg) |

| Breaking elongation | 180% |

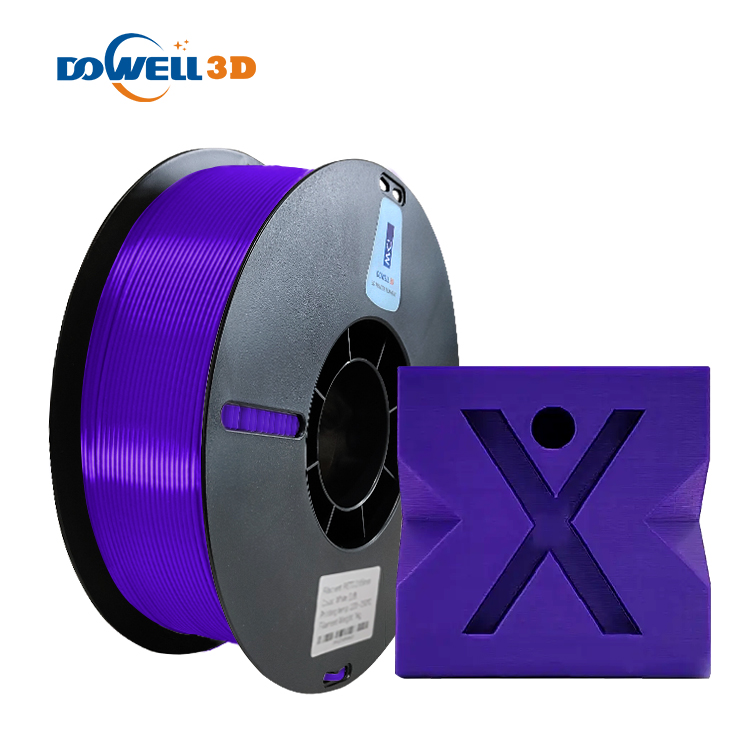

| Color | White,black,grey,blue,green, transparent, etc... Contact us for more color details. |

| Net weight | 1kg /3kg /5kg |

| Advantages | Eco-friendly; no bubble; low shrinkage; high strength; neat winding,constant diameter. |

| Customization | Color, packaging, Logo |

Derived from corn, biodegradable, non-toxic

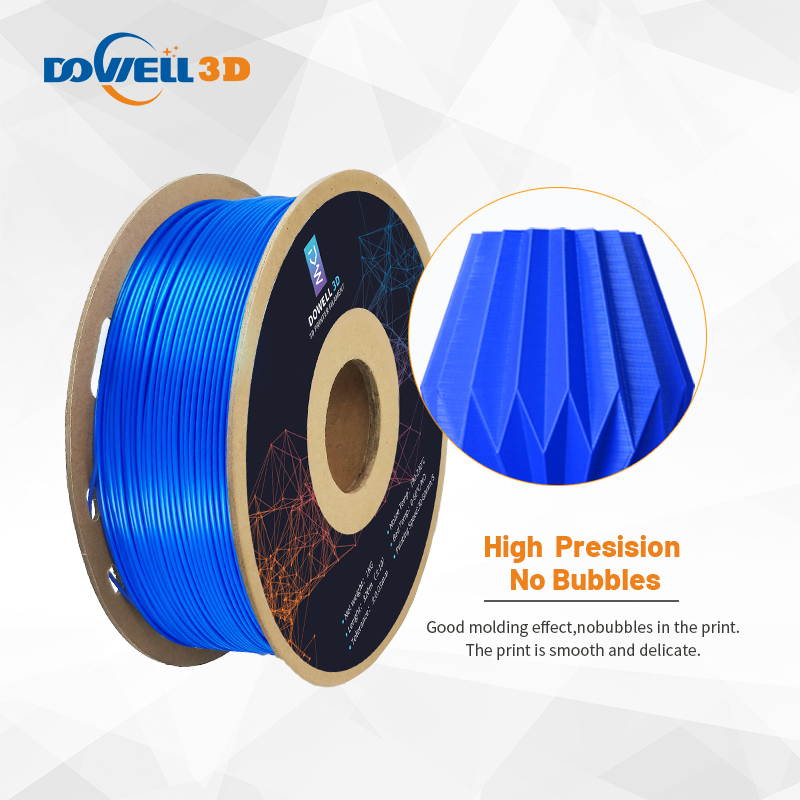

High Diameter precision 1.75mm (±0.02),never worry about blocking the nozzle during the printing process because of the unstable diameter.

Neat winding, help you easy achieve smooth print.

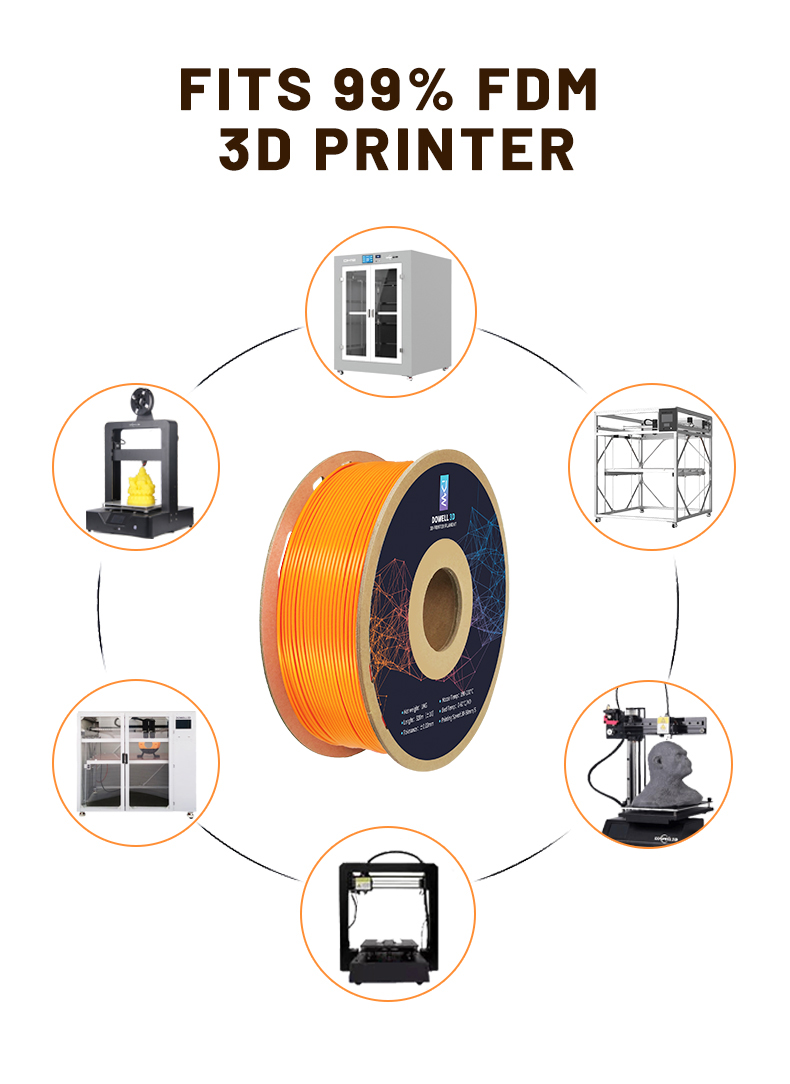

Fits all almost 3d printers and 3d pen that use FDM filament

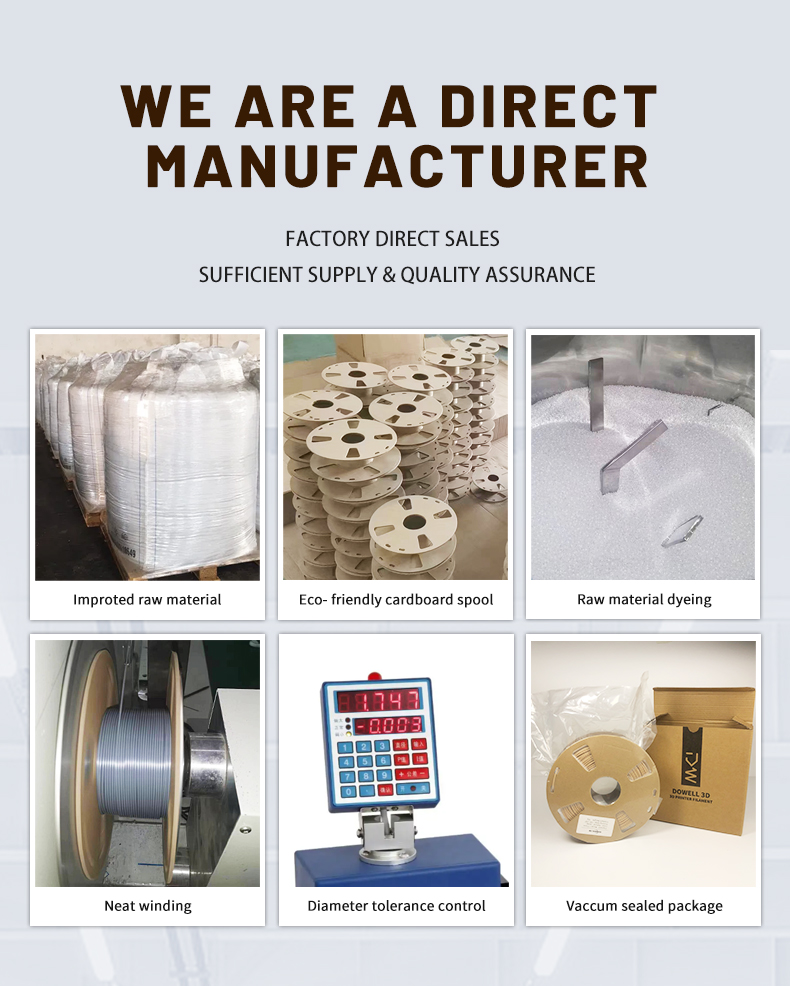

Production Control

1. Produce process

Before produce extruding filament, we will dry the raw materrial of PLA for a enough time

Mix with colors masterbatch or colors powder, all which certified with ROHS.

Adjust temperature and dragging rate , make filament diameter range at 1.75mm, ±0.02mm, each spool net weight 1kg/3kg/5kg.

2. Production quality control

Diameter laser detect kits to control extruding rate on line, when diameter smaller or higher than accept range, the laser detect kits will adjust the extruding rate higher or smaller to make diameter range at acceptable.

3. Winding

We have professional and advanced equipment that can arrange each roll of 3d printing material PLA filament neatly. There is no need to worry about stopping printing because of filament tangle in the printing process.

4. Packaging

Each spool packed in seal vaccum bag, never have to worry about moisture. each spool in a box, 10 boxes in a carton.

5. Research, developing, and other option service.

We have engineers that specialty in color formulation ,plastic modification, packaging, quality control ,producing control, we can do according to your requirements .

We offer customization service for custom make color, logo, packaging.