Custom 3d Printer Filament PLA Carbon Fiber 3d Printer Materials Dowell PLA CF 1.75mm 2.85mm 3d Printer Plastic Rod

- Dowell 3d

- China

- 10 -14 days

- 10000kg/week

Environment-friendly filament.

Vacuum sealed with desiccant for packing and Special express cartons protect filaments from damage.

Good ductility, impact resistance, high strength and rigidity.

Carbon fibre is strong, yet lightweight.

Company Profile

Luoyang Dowell Electronic Technology Co., Ltd. was established on December 31, 2014. We focus on developing innovative products such as large-scale 3D printers and 3D printing filaments, and our R&D personnel have expertise in product engineering and quality control management. The company is committed to the research and innovation of 3D printer filaments, providing customers with high-quality, affordable 3D printing filaments and a high-quality experience.

Dowell 3D Printer Filament PLA Carbon Fiber1.75/2.85mm

| Specification Of Dowell 3D PLA Carbon Fiber Filament | |

| Product | PLA Carbon Fiber filament |

| Diameter | 1.75mm 2.85mm |

| Tolerance | ±0.02mm |

| Print temp | 190-230°c |

| Bed temp | 50-70°c |

| Print speed | <200mm/s |

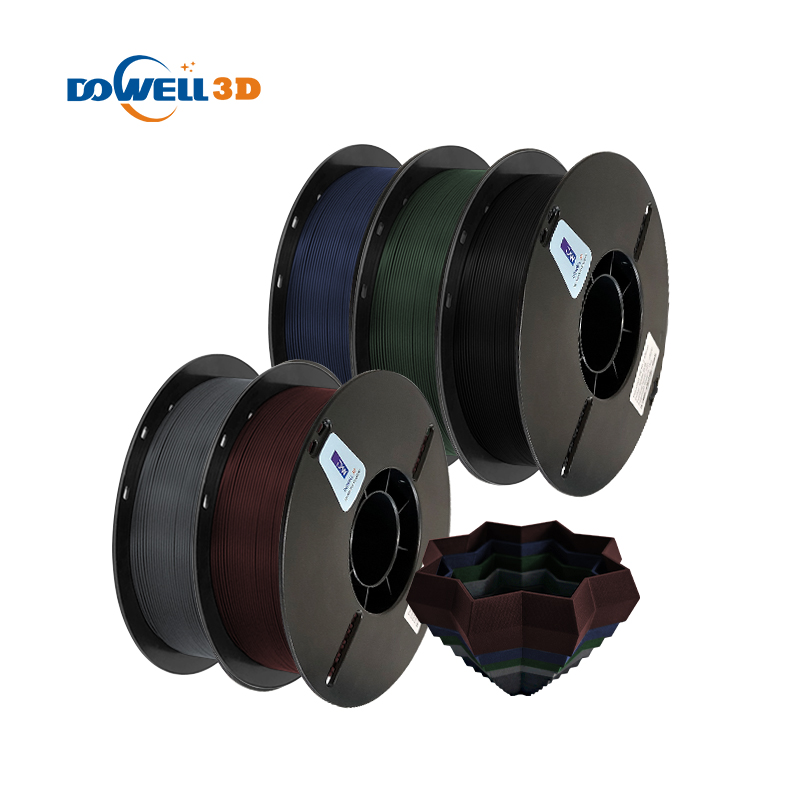

| Color | 5 colors : Black, Navy Blue, Gray, Ochre Red, Army Green |

| Roll size | 1kg /3kg /5kg |

| Advantages | Break through the wood characteristics to ensure no plug, no edge, printing products strong, not easy to break, can be polished processing, easy to remove support, high toughness, fast solidification to save printing time. |

| Customization | Inner box, packaging, Logo |

Five Colors Available

Product Parameters Details

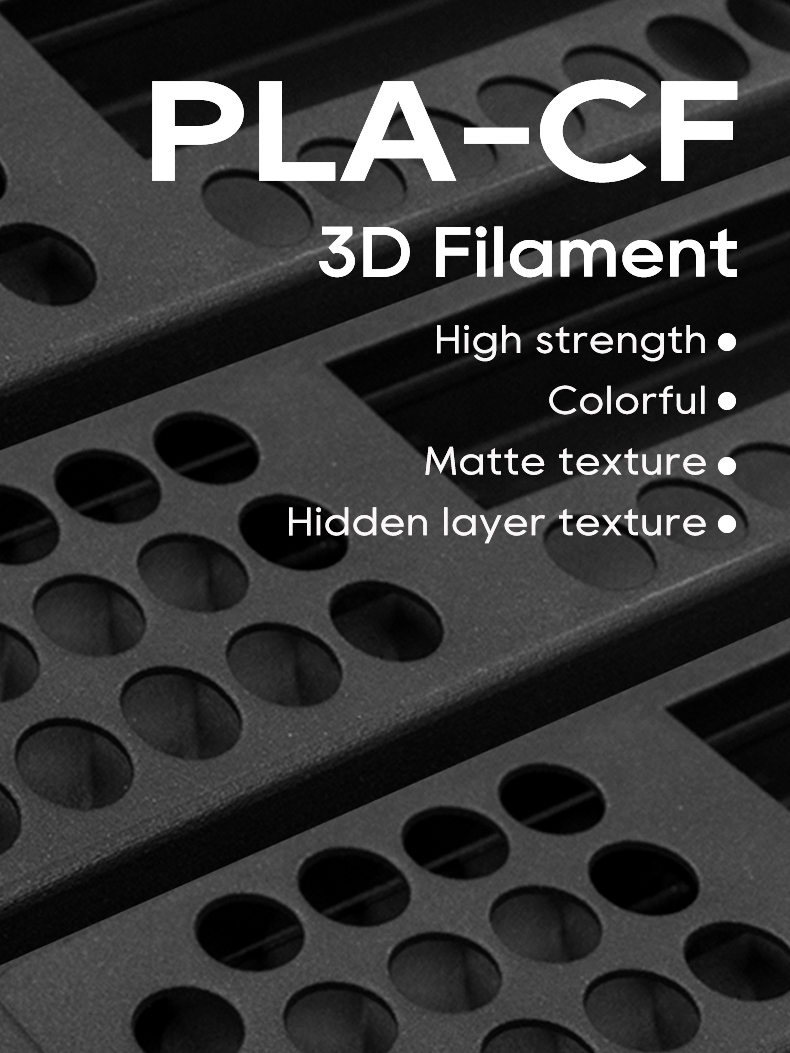

PLA Carbon Fiber Filament Product Description

PLA carbon fiber 3D filament has the features that high strength, colorful, matte texture and hidden layer texture.

- PLA carbon fiber based on PLA polylactic acid as raw material, high-quality carbon fiber raw materials are added to enhance the strength and modulus of PLA. At the same time, the addition of carbon fiber also brings a matte appearance and unique carbon fiber matte texture to PLA. PLA carbon fiber filament can be used as a structural part or an exterior part.

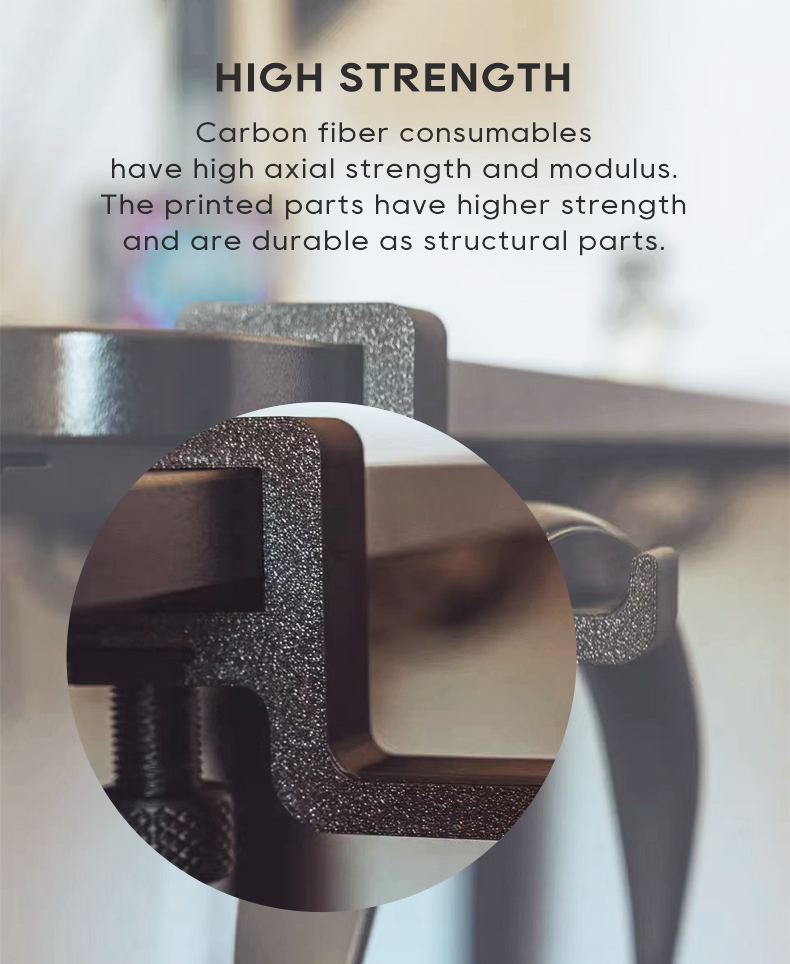

PLA carbon fiber 3D filament has the features that high axial strength and modulus.The printed parts have higher strength and are durable as structural parts.

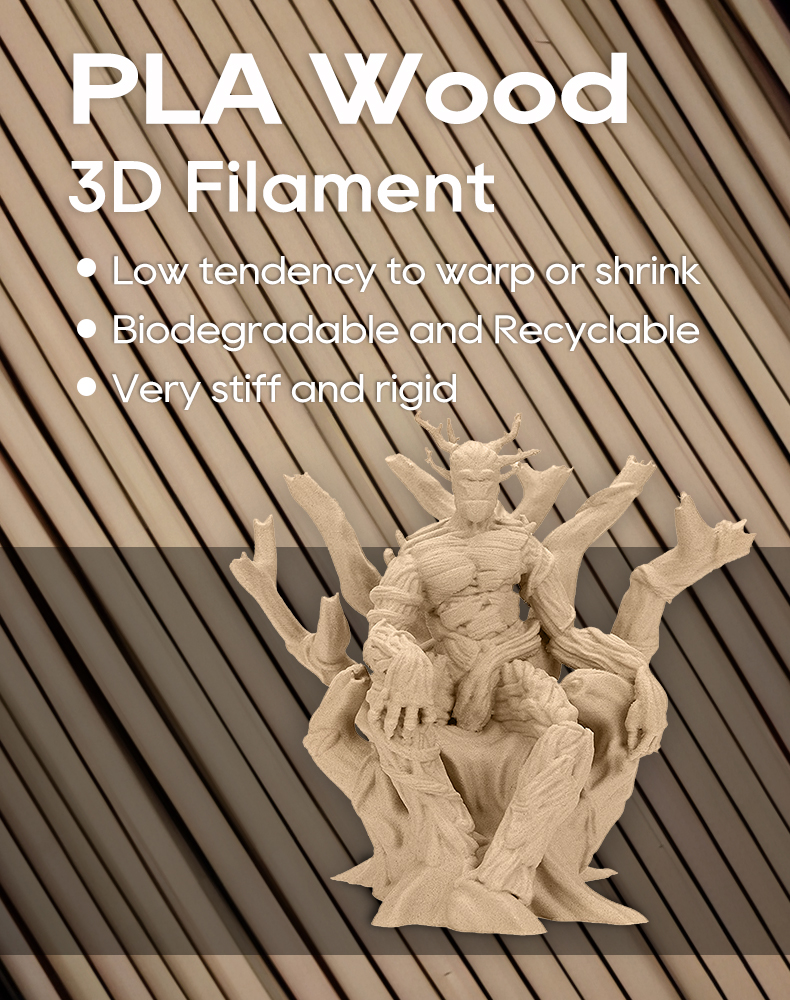

Dowell 3D PLA wood filament has the advantage of high toughness and easy to remove support. PLA wood filament can be polished and solidified quickly to save printing time.

PLA Wood 3D filament has the features that low tendency to warp or shrink, biodegradable and recyclable and very stiff and rigid.

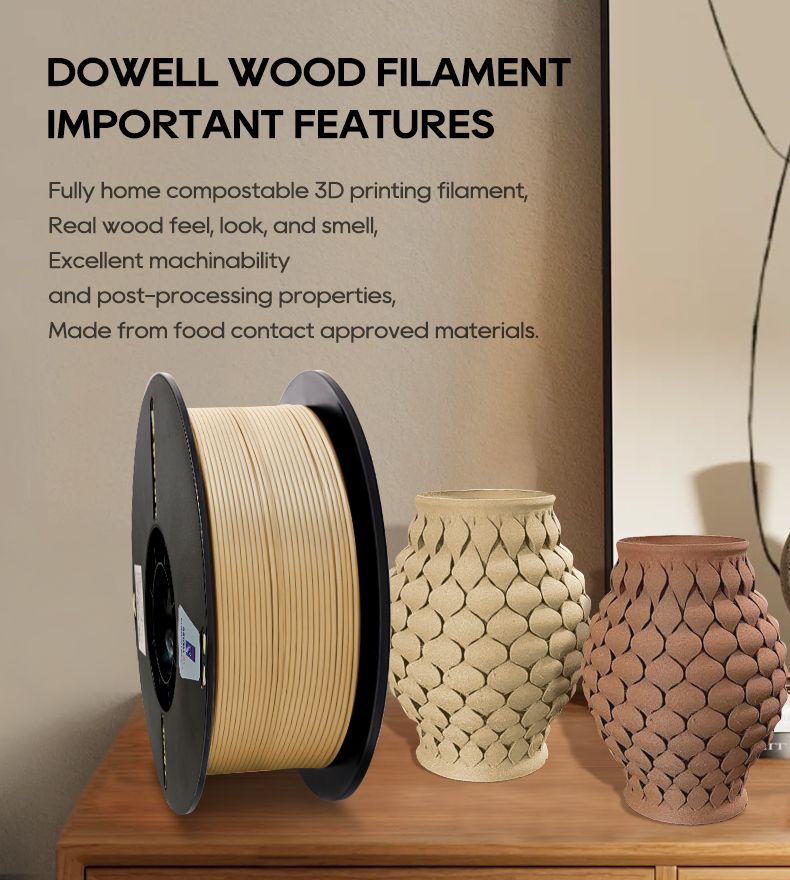

Dowell wood filaments are fully home compostable 3D printing filaments that have the feel, look and smell of real wood, as well as excellent machinability and post-processing properties. And made from food contact approved materials.

PLA Wood filament has the advantage of high precision. The diameter tolerance is controlled at ±0.02mm during the production process. The nozzles are not blocked during the printing process, making the surface of the printed model smooth.

PLA Wood filament has the advantages of neat wiring, stable output and smooth extrusion. Ensure that the filaments are not tangled or knotted during the printing process, making printing easy and perfect.

Printed model display.You can give full play to your imaginative brain to design the interesting models you want, and then print them out with a 3D printer.

Each filament spool uses a plastic spool, and transported in vacuum packaging and special express carton to ensure that it will not deform during transportation.

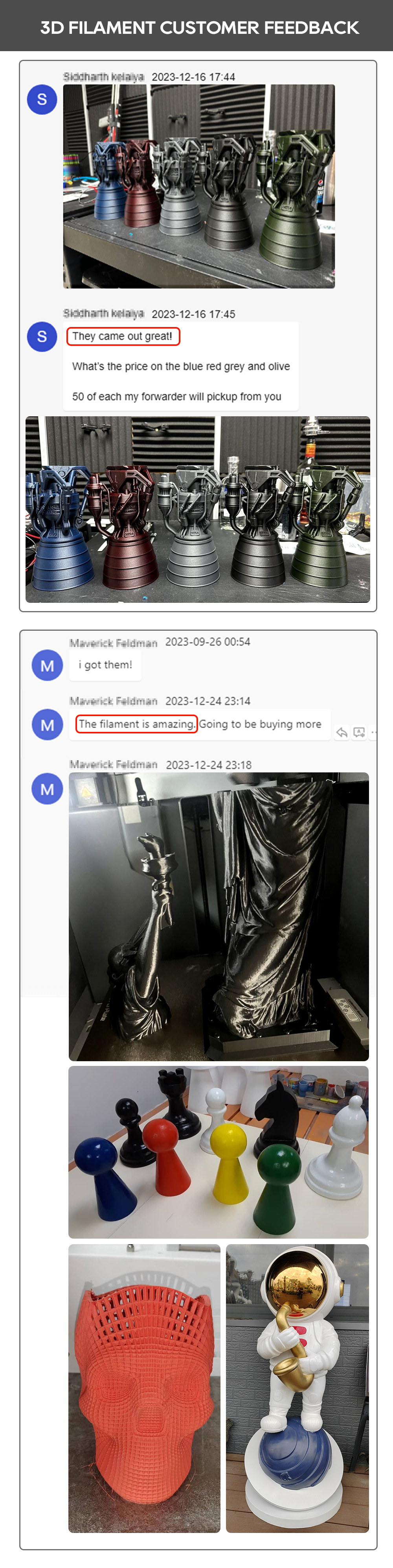

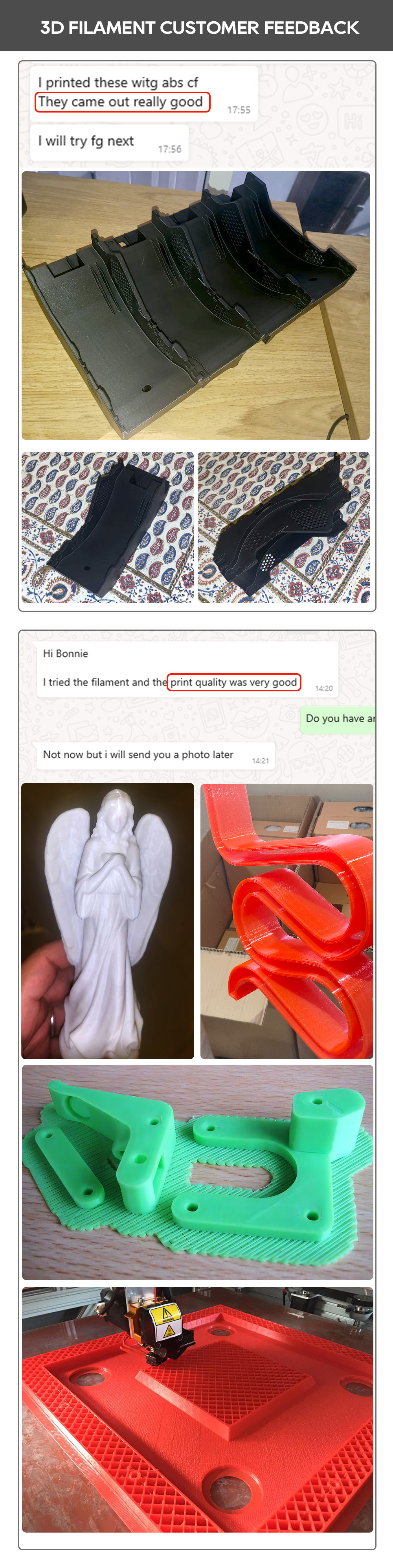

Dowell 3d Filaments Consumer Feedback

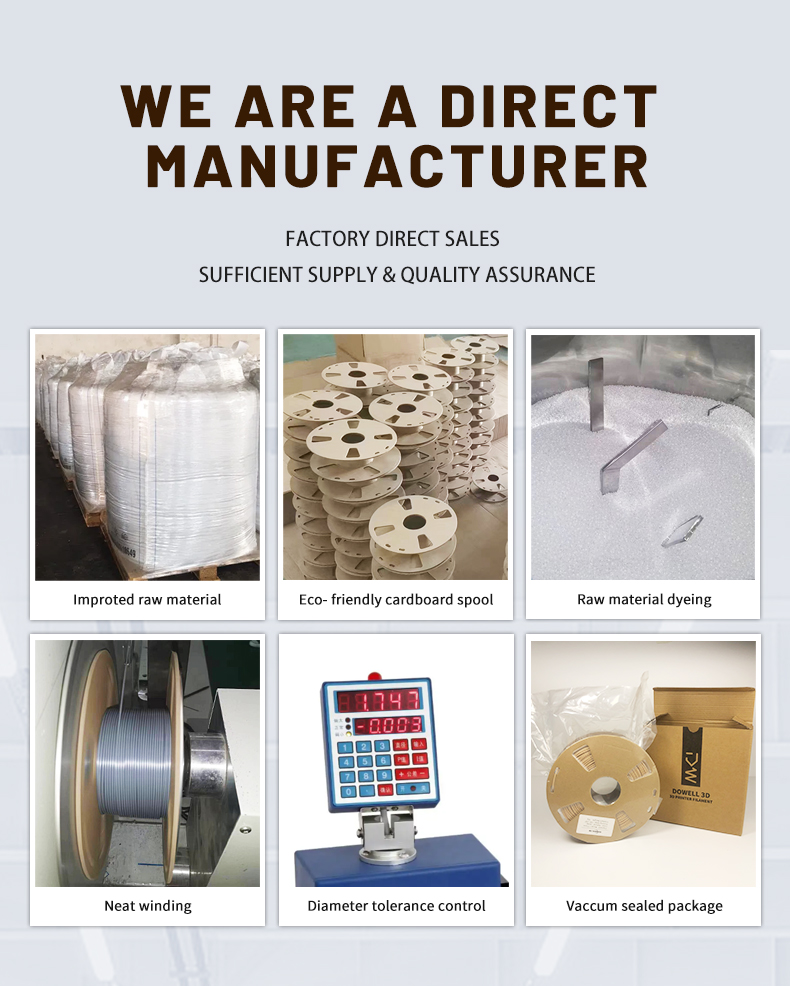

Production Control

1. Produce process

Before produce extruding filament, we will dry the raw materrial of PLA for a enough time

Mix with colors masterbatch or colors powder, all which certified with ROHS.

Adjust temperature and dragging rate , make filament diameter range at 1.75/2.85mm, ±0.02mm, each spool net weight 1kg/3kg/5kg.

2. Production quality control

Diameter laser detect kits to control extruding rate on line, when diameter smaller or higher than accept range, the laser detect kits will adjust the extruding rate higher or smaller to make diameter range at acceptable.

3. Winding

We have professional and advanced equipment that can arrange each roll of 3d printing material PLA filament neatly. There is no need to worry about stopping printing because of filament tangle in the printing process.

4. Packaging

Each spool packed in seal vaccum bag, never have to worry about moisture. each spool in a box, 10 boxes in a carton.

5. Research, developing, and other option service.

We have engineers that specialty in color formulation ,plastic modification, packaging, quality control ,producing control, we can do according to your requirements .

We offer customization service for custom make inner box, logo, packaging.

Why Choose Us

Storage And Usage Suggestions

When replacing filaments, be sure to hold the tip tightly and do not slip from your hands to prevent the filaments from knot and wrap the thread!

We recommend that you place it in a dry enviroment (relative humidity less than 20%) during normal storage or use. Please keep it sealed when not in use; please use the opened filaments as soon as possible. If the filament has become damp, it is recommended to dry it in an oven to eliminate the moisture absorbed into the filament before use.