PLA vs PETG: Which Material Should You Choose?

PLA vs PETG: Which 3D Print Material Should You Choose?

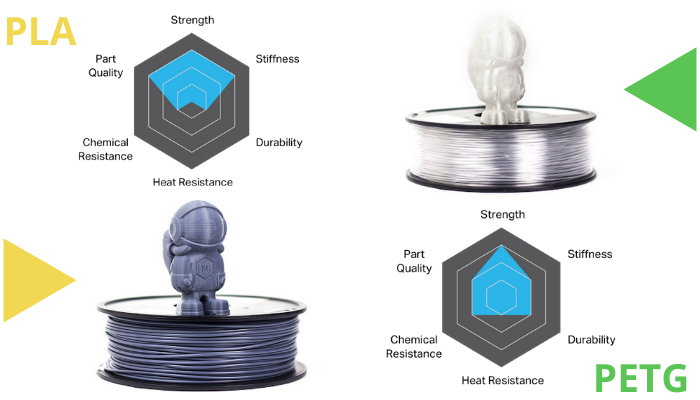

When most people think about 3D printing, the material that comes to mind is usually plastics. Though there are, of course, other materials, including metal and ceramic, polymers still make up the majority of the market for 3D printing materials. This is because they can be used not just for industrial applications, like prototyping, but they are also often the material of choice for desktop printers, especially those using fused deposition modeling (FDM) processes. Out of the various materials falling under the category, two of the most popular are PLA and PETG. Known for ease of printing, these two materials are made into filaments that can be used by both beginners and experts with FDM printers. Though they are similar in several key ways, there are still significant differences between the two filaments. So what are the characteristics of the materials? How do they differ? When would you use one over the other? We took a closer look at both PLA vs PETG, comparing them to help you find the answers to these important questions and more!

Characteristics

One of the major differences between PLA and PETG is of course how the two materials are made. PLA is known for being made out of renewable and natural raw materials like corn. It is also biodegradable under the correct conditions, making it a popular choice for those who are looking for sustainable, environmentally-friendly materials. On the other hand, PETG is famously made out of PET, a well known thermoplastic. In order to create PETG, glycol (G) is added to PET (Polyethylene terephthalate) at the molecular level. PETG has a greater strength and durability and most importantly for 3D printing it is more flexible than PET, preventing it from becoming brittle when printed. Though PETG is 100% recyclable, it is an oil-based polymer meaning it is not biodegradable like PLA as it is not made out of raw materials.

Ease of Printing

Moving beyond the base of the material,, there are definitely similarities between both polymers when it comes to technical characteristics. For example, they are both known for being easy to print with. In fact, PLA is one of the easiest, if not the easiest, materials to print with in 3D printing. This, understandably, has made it popular with beginners. Much of this comes down to heating, PLA can be printed at much lower temperatures and requires neither a heated printing bed nor a closed chamber. In terms of extrusion temperature, between 190-220℃ (374-428℉), is ideal for PLA, which is less than for PETG.

PETG is also considered one of the easier materials to print with, though less than PLA. A major part of that is that PETG also does not need a closed chamber. However, due to higher temperature requirements, a heated printing bed is required for PETG, limiting perhaps the choice of printers for some users. PETG generally prints at a higher temperature than PLA, with an extrusion temperature between 220° and 260°C necessary for optimal printing. Additionally, the Heating Bed Temperature should be between 75-90 °C. One thing to note however, is that while it can be difficult initially to start printing with PETG (unlike PLA which can be printed with extreme ease from the get go), once you have the correct settings PETG is also known for being an easily extruded material with good thermal stability. Another thing to consider for both materials is that as they are high viscosity materials, they can clog printer heads. However, this is the case with many other plastics and should not necessarily be taken as a mark against either material.